Since the launch of the KIRI Engine API, its usability and real-world integration have been closely monitored. The CEO of KIRI Innovations, Jack, met with the creator of NIX Dive Mask, Dr. William Sikkema, to explore the intricacies of this problem-solving initiative and the role scanning technology plays in enabling it.

Rethinking Fit and Vision: The Case for Custom Dive Masks

Scuba diving presents a unique set of challenges for gear design, especially when it comes to masks. Refraction alters underwater vision, making accurate perception difficult. Generic sizing and rigid shapes often fail to accommodate the diverse range of human facial structures, leading to discomfort or improper sealing. And for divers who require vision correction, most consumer-grade options overlook the need for prescription lenses entirely.

These issues are more than inconveniences: they can impact safety, performance, and the overall diving experience. Recognizing this gap, William from NIX Dive Mask, in partnership with KIRI Engine, developed a pipeline centered on personalization: masks that are tailored to the user's face and visual needs.

NIX Dive Mask's Home Page

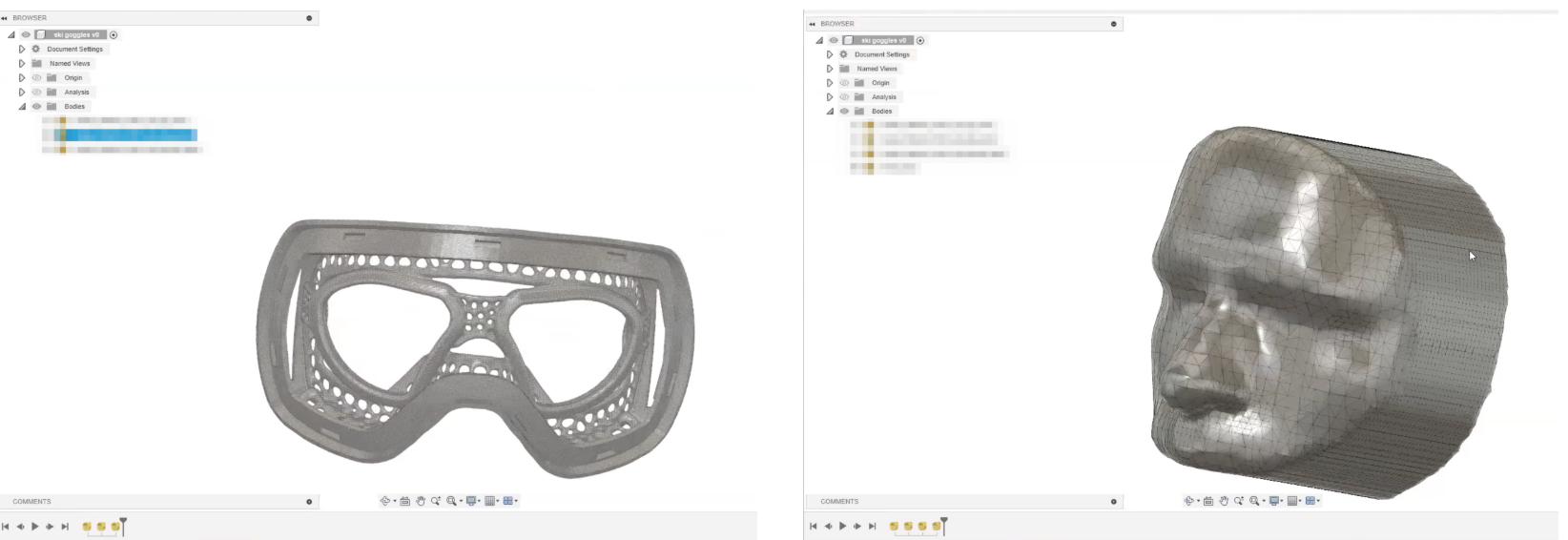

To accomplish this, NIX incorporates facial scanning into its product pipeline—allowing users to capture 3D data of their face from just a short video. That data is then used to inform the geometry and lens placement of each mask, solving for fit, comfort, and prescription accuracy. This process is made possible through the integration of KIRI Engine's 3D scanning API, which supplies the infrastructure needed to gather, process, and apply user-specific spatial data directly within NIX's workflow.

How NIX Reimagines Dive Mask Customization

NIX Dive Mask reimagines dive gear from the ground up by centering the design process around the individual user. Rather than adapting to generic sizing, each mask is custom-built based on 3D facial data, allowing for a fit that aligns precisely with the user's bone structure and facial contours.

The process starts with a guided photo capture workflow. Users take 30 photos of their face using a smartphone, following step-by-step instructions that ensure proper angles, consistent lighting, and a neutral expression. These images are then processed into a detailed 3D mesh via KIRI Engine's photogrammetry API, which supplies the geometric foundation for each mask. This enables a level of customization that minimizes pressure points, improves seal integrity, and increases comfort during extended dives.

NIX also addresses a longstanding oversight in mainstream dive gear: prescription compatibility. Users can upload their vision prescription and measure their interpupillary distance through a web-based tool. With this data, NIX integrates custom-ground lenses directly into the mask's design, aligned precisely to the user's optical requirements. This removes the need for workaround solutions and ensures visual clarity underwater, where depth perception and focus are critical.

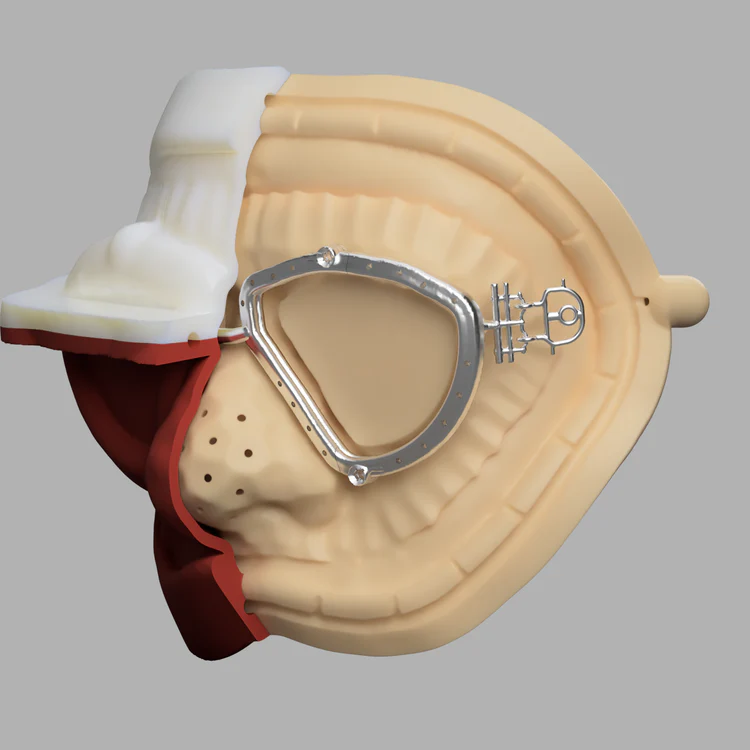

Molding&Construction of the Mask

By combining accessible scanning, personalized fit, and built-in optical correction, NIX tackles three persistent pain points in one cohesive product experience—made possible through practical implementation of 3D scanning and digital manufacturing.

From Face Scan to Finished Product: The Workflow Behind the Mask

The level of personalization is made possible by a backend pipeline that's as thoughtful as the product itself. Rather than asking users to interact with complicated scanning software or external tools, NIX keeps the process lightweight and intuitive.

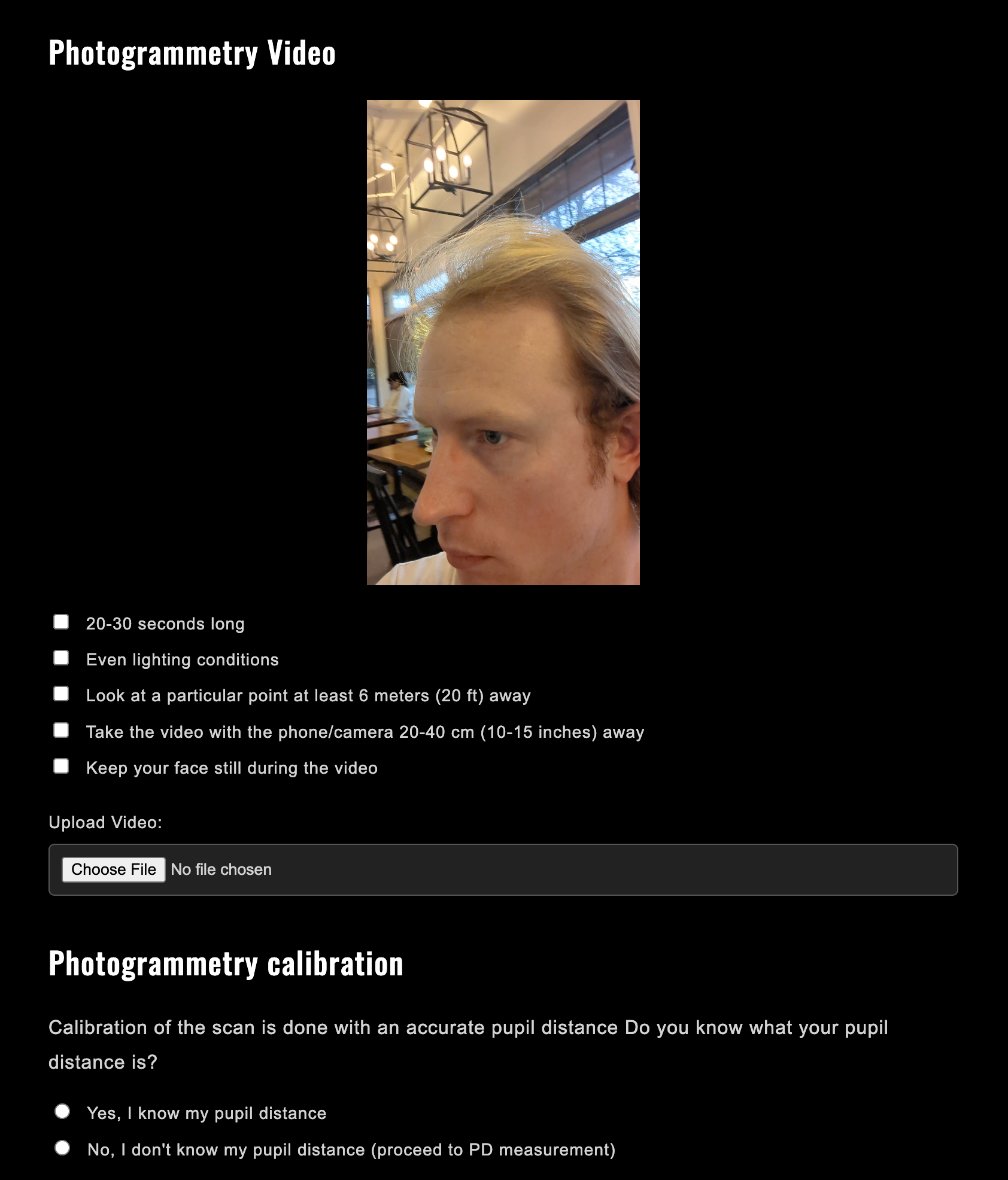

Users begin by uploading a short video—20 to 30 seconds in length—captured under guided conditions that ensure sufficient lighting, distance, and stillness. This video is processed through the KIRI Engine API, which extracts a high-accuracy 3D mesh of the user's face. The API handles frame selection, reconstruction, and mesh optimization, returning a watertight model ready for downstream use.

Scanning Guidelines (from NIX's Website)

For users requiring prescription lenses, the system prompts for additional calibration data. Interpupillary distance can either be entered directly or estimated from a reference photo taken with a standard-sized card. Once prescription values are filled in—covering sphere, cylinder, and axis for each eye—this information is integrated into the design phase to ensure proper lens positioning and optical correction.

By embedding KIRI's API directly into its submission workflow, NIX maintains full control over scan quality and scaling while keeping the front-end process simple and accessible. The result is a user experience that feels effortless, supported by a backend infrastructure capable of delivering precise, individualized results—at scale.

Comfort, Clarity, and Confidence: The Diver's Perspective

While the technical workflow behind each NIX Dive Mask is invisible to the end user, Jack was able to gain some insights into the production and molding of these lensed masks.

A glimpse into NIX's mask production pipeline

Through customizations and tailored fits, a properly fitted mask can transform the diving experience—eliminating distractions, reducing fatigue, and allowing divers to stay submerged longer with greater focus.

The custom-fit design addresses issues many divers assume are unavoidable: pressure points on the forehead or cheekbones, air leaks from ill-fitting seals, or the need to constantly adjust the mask mid-dive. By conforming exactly to the user's facial geometry, NIX masks minimize these friction points entirely.

The impact is just as significant when it comes to vision. With prescription lenses calibrated to the user's optical data and aligned directly to their 3D facial model, the masks restore clarity without compromise. Whether scanning gauges, observing marine life, or navigating intricate underwater terrain, divers gain access to sharper, undistorted visuals that would be difficult, if not impossible, to achieve with standard gear.

Taken together, these improvements support more than comfort and visibility—they build confidence. In an environment where spatial awareness, endurance, and composure matter, having equipment that fits seamlessly can make all the difference.

Rethinking Personalization in Product Design

NIX Dive Mask's integration of 3D scanning technology illustrates a broader shift in how personalized products can be developed and delivered. Rather than treating customization as a premium add-on, the system treats it as a design baseline—an expectation, not an exception. And with tools like KIRI Engine's API, the technical barriers to achieving that baseline are lower than ever.

KIRI Engine API Homepage

By embedding photogrammetry and calibration into a lightweight, user-driven workflow, NIX has demonstrated how even complex, performance-critical gear can be adapted to individuals at scale. The result is a product that doesn't just solve technical problems—it reshapes the user experience from the ground up.

As more industries adopt 3D scanning and parametric design, pipelines like this one point to a future where personalization is built into the infrastructure, not layered on top. For KIRI Engine, it's a testament to how accessible, developer-friendly scanning tools can serve as the foundation for truly human-centered design.