Why Print Speed Matters

When it comes to 3D printing, speed is more than just a convenience—it's a key factor that can influence workflow, productivity, and even creativity. Whether you're a designer prototyping a new product, a hobbyist eager to bring ideas to life, or a small business managing print-on-demand jobs, print speed directly impacts how quickly you can move from concept to reality. In time-sensitive scenarios, the difference between a six-hour print and a three-hour print could mean hitting or missing a deadline.

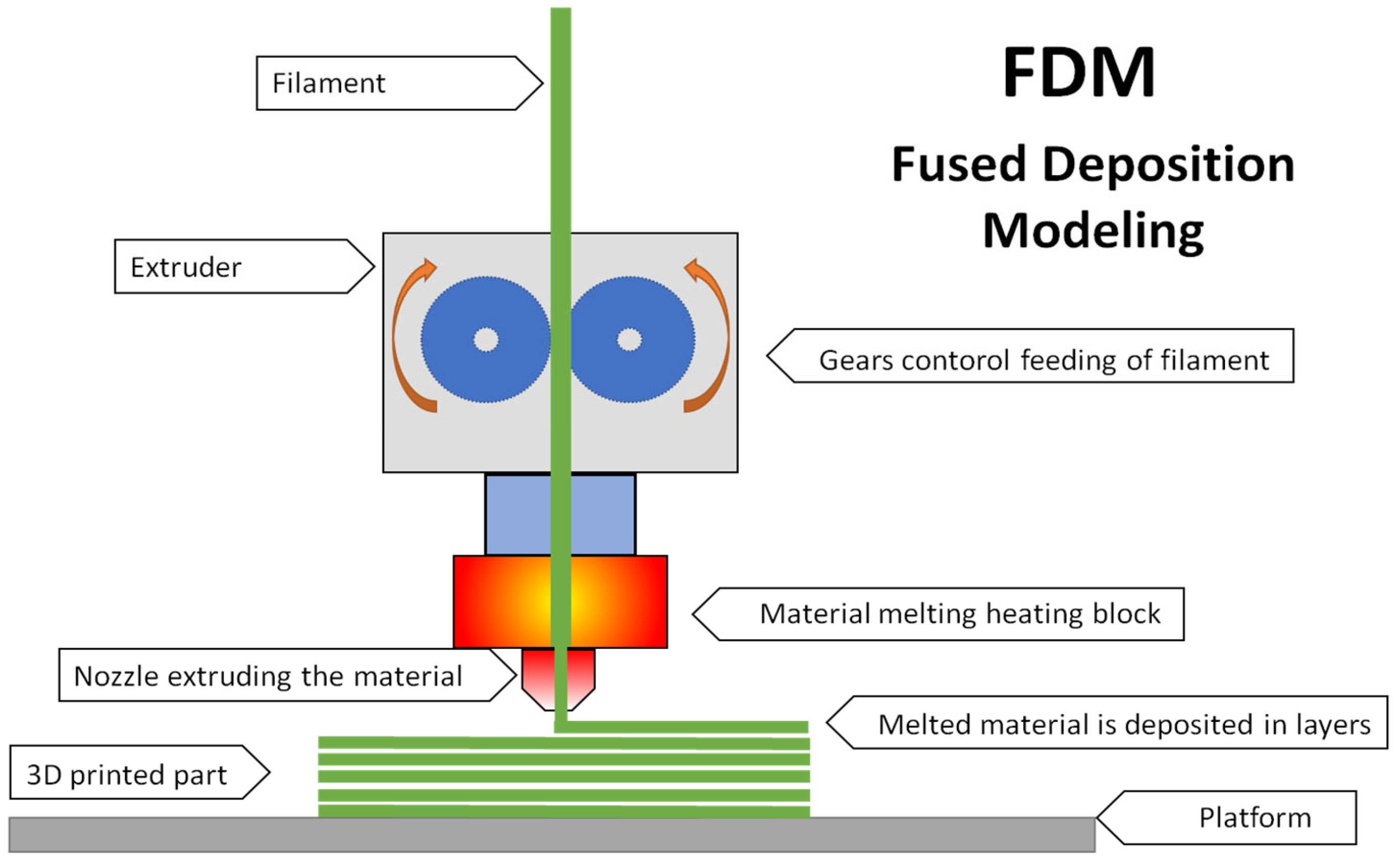

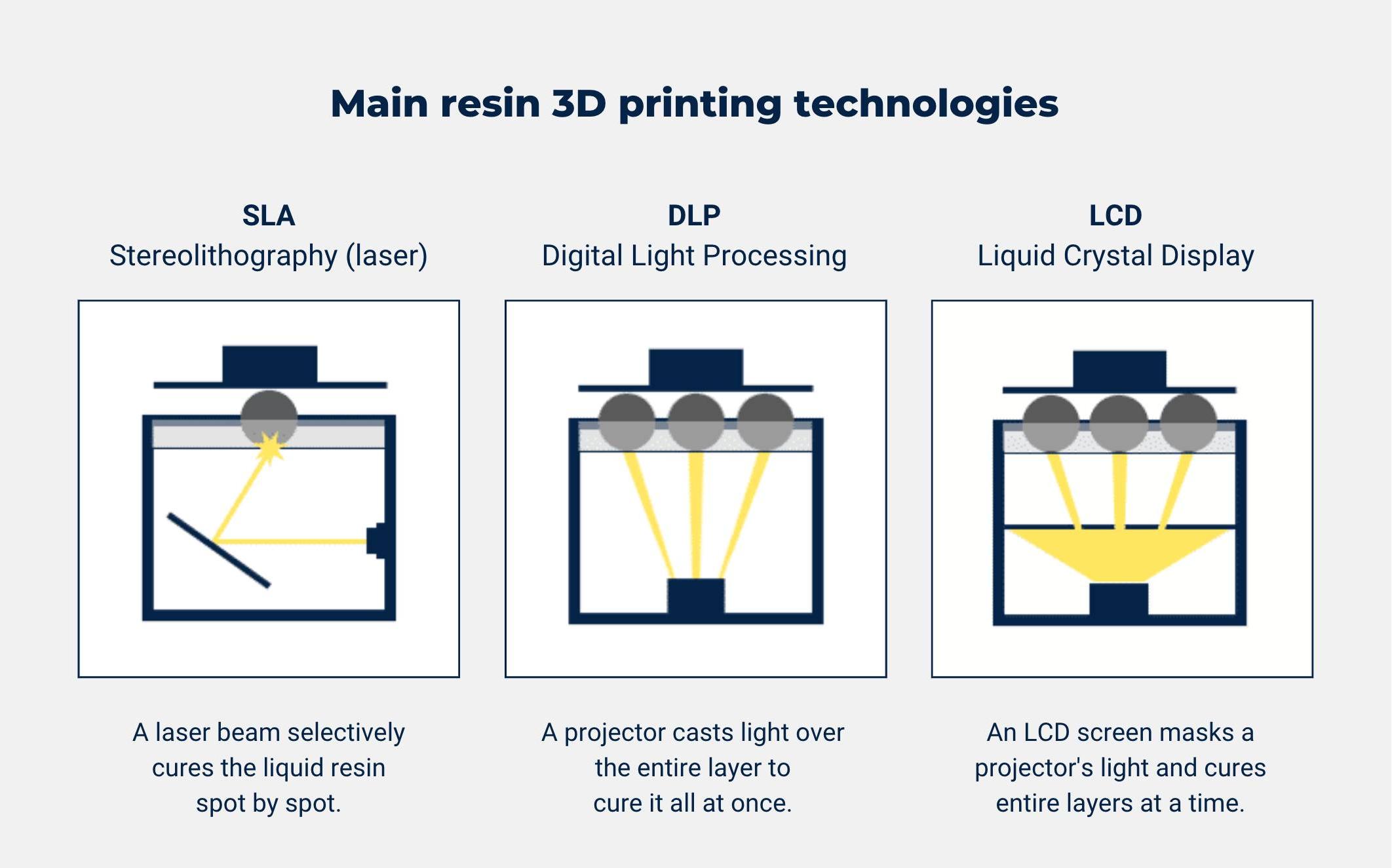

There are two primary types of consumer-level 3D printing technologies: Fused Deposition Modeling (FDM) and resin-based printing, which includes SLA(Stereolithography), DLP(Digital Light Processing), and LCD(Liquid Crystal Display) methods. FDM printers extrude melted thermoplastic filament layer by layer, while resin printers use light to cure liquid photopolymer resin into solid layers. Each method has unique advantages and drawbacks, but one of the most common questions for anyone choosing a 3D printer is: which is faster—FDM or resin?

This article explores the key differences in speed between these two technologies, breaks down what factors affect print time, and helps you decide which method is best suited for your needs—whether you're looking for the fastest 3D printer or the most balanced solution between speed and quality.

What Affects 3D Printing Speed?

Before comparing FDM and resin 3D printing technologies directly, it's important to understand the factors that influence print speed across both methods. While different technologies have their own limitations, several shared and unique parameters play a role in how fast a 3D model is completed.

Layer Height and Print Detail

Layer height refers to the thickness of each individual layer in a 3D print. A smaller layer height (e.g., 0.05 mm) means more layers are required to complete the model, resulting in finer surface details and smoother finishes. However, this also increases print time. Conversely, a larger layer height (e.g., 0.2 mm) completes prints faster but may lead to visible layer lines and less detailed surfaces. Both FDM and resin printers support adjustable layer heights, though the impact on speed and surface quality is often more significant with intricate or detailed prints.

Print Volume and Model Size

The bigger the object, the longer it takes to print. Large models require more material, more layers, and more movement. In resin printing, the speed is generally consistent across the layer, regardless of how many objects are printed—whereas in FDM, more objects or larger surfaces increase time substantially.

Infill Settings (FDM Only)

FDM printers allow users to control how solid a model is using infill percentage. A model printed at 20% infill will be much faster than one printed at 100%, and infill patterns (like honeycomb or grid) also affect speed. Resin printers don't use infill the same way since models are typically hollowed out in the slicing process.

Curing Time and Layer Exposure (Resin Only)

In resin printing, each layer is cured using light exposure. The time it takes to cure a layer depends on the printer's light source (LCD, DLP, or laser) and the resin's sensitivity. Faster printers cure layers in seconds, but thicker layers or complex geometries may require longer exposure.

Movement Mechanics

In FDM printing, the nozzle moves in X, Y, and Z directions, and faster motors or lightweight extruders improve speed. In resin printers, only the build platform moves vertically (Z-axis), and the entire layer is cured at once (especially in LCD/DLP), offering speed advantages in multi-object or batch printing.

Printer Firmware and Slicer Optimization

The slicing software and firmware can optimize paths, reduce travel time, and minimize unnecessary movements. Modern printers use algorithms to improve print efficiency, but the impact is often more noticeable in FDM than resin.

FDM Print Speed: How Fast Can It Go?

Fused Deposition Modeling (FDM) is one of the most popular 3D printing technologies due to its affordability, accessibility, and wide material support. But when it comes to print speed, FDM printers vary greatly depending on several hardware and software factors.

Typical Speed Range

Most consumer-grade FDM printers operate at speeds ranging from 40 to 100 mm/s, with some tuned setups reaching up to 150 mm/s. However, going faster usually comes at the cost of surface quality and dimensional accuracy. In professional or industrial setups with rigid frames and advanced motion systems, speeds above 200 mm/s are achievable.

Fastest FDM Printers

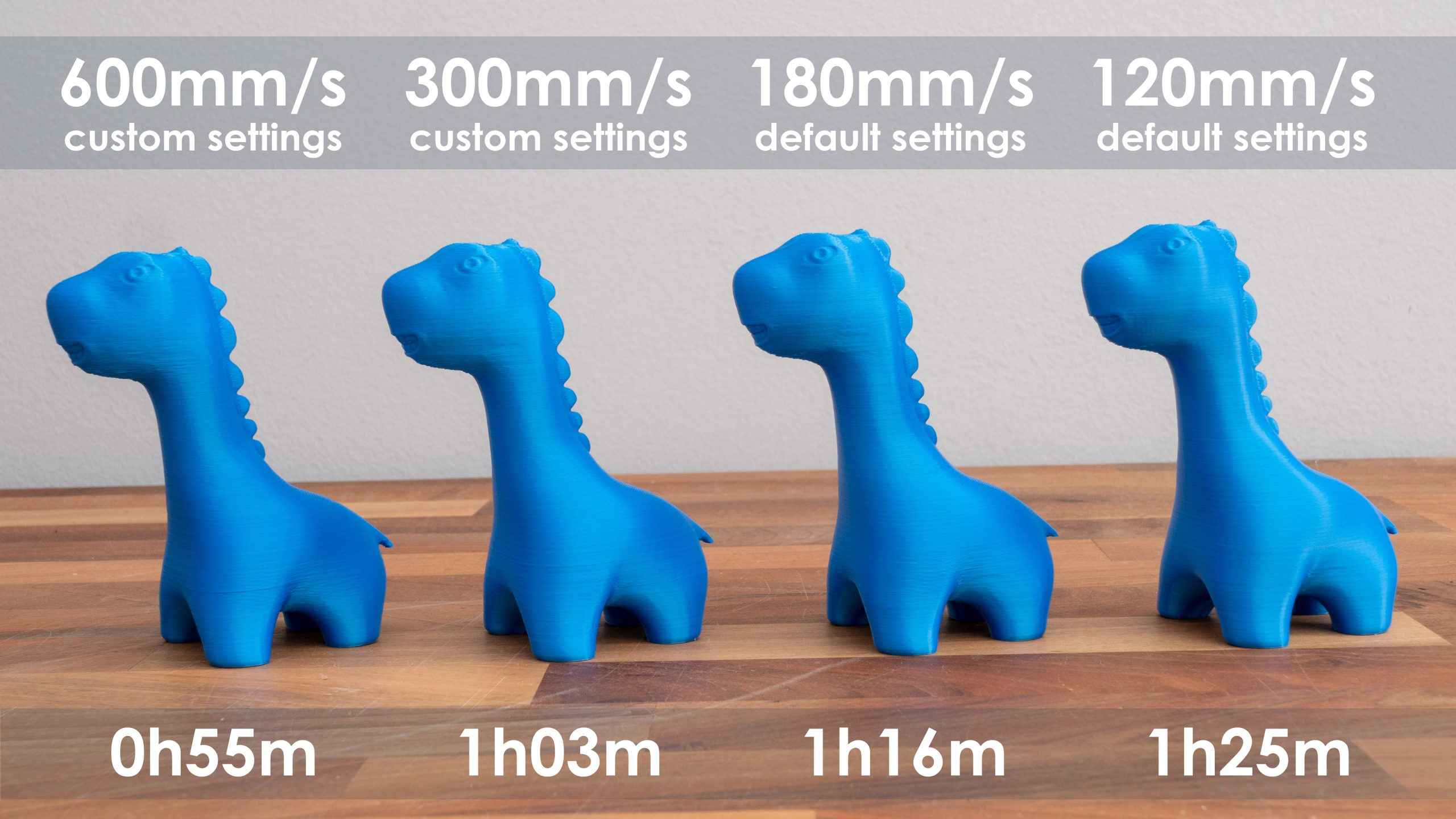

Creality K1 Max Print Quality Comparison With Four Different Speeds From 120mm Per Second To 600mm Per Second Scaled

Some modern FDM printers are optimized for speed. For example:

Bambu Lab X1 Carbon: Uses a CoreXY structure and active vibration compensation, reaching up to 500 mm/s while maintaining quality.

Prusa MK4: Offers excellent reliability with speeds up to 200 mm/s, supported by input shaping firmware.

Creality K1: Also boasts high-speed CoreXY mechanics, hitting 600 mm/s in some conditions.

These machines represent a new generation of fast FDM printers using technologies like input shaping and pressure advance to maintain speed without sacrificing quality.

When Speed Becomes a Trade-Off

Although high-speed FDM printing is now more accessible, it still involves trade-offs:

Detail Loss: Faster speeds reduce the precision of small features.

Poor Adhesion: Layers may not fuse properly at high speeds if temperature isn't adjusted accordingly.

Mechanical Wear: Constant high-speed printing can increase the wear on belts, bearings, and extruders.

For hobbyists or small-batch prototyping, the balance between speed and quality must be carefully tuned. Fortunately, slicers like Cura or PrusaSlicer offer customizable profiles to help optimize prints for speed.

Resin Print Speed: How Fast Is It Really?

Resin 3D printing, particularly SLA and MSLA (Masked Stereolithography), is known for its exceptional detail and smooth surface finish. While traditionally thought of as slower than FDM, modern resin printers have seen significant speed improvements in recent years.

How Resin Printing Works and Its Speed Implications

Unlike FDM printers, which build models line-by-line, resin printers cure entire layers at once using a UV light source and LCD mask. This means the time it takes to print each layer is fixed, regardless of how many objects are on the build plate—as long as they fit.

Typical Layer Cure Time: 1.5 to 3 seconds per layer

Average Print Speed: Often around 20-30 mm/hour in Z-axis height, though newer machines can reach 60-100 mm/hour

This makes resin printing highly efficient for printing multiple small objects at once, as print time is determined by height, not volume.

Fast Resin Printers in the Market

Several modern MSLA printers now focus on speed without sacrificing quality:

Anycubic Photon Mono M5s: Uses a fast 12K monochrome screen with layer curing as fast as 1.5 seconds.

Elegoo Saturn 3 Ultra: Includes fast printing mode with enhanced light source and efficient cooling, pushing up to 150 mm/h in some conditions.

Phrozen Sonic Mega 8K: Offers a large build plate with fast monochrome LCDs for faster layer exposure.

These advancements make resin printers faster than ever, particularly for mass-producing small, detailed parts.

Factors That Influence Resin Print Speed

Layer Height: Thinner layers mean more steps and slower prints.

Lift Speed & Delay: After curing, the build plate must lift and reset. Faster mechanical movements = faster prints.

Resin Type: Some fast-curing resins are optimized for speed and reduce exposure times dramatically.

Speed vs Quality in Resin Printing

Though fast, speeding up resin prints has its own challenges:

Suction Forces: Faster lift speeds can cause layer separation or failure.

Overexposure or Underexposure: May result in brittle or incomplete models.

Post-processing: Cleaning and curing still take time and affect total workflow speed.

FDM vs Resin: Which Is Faster?

When comparing FDM and resin 3D printing in terms of speed, the answer isn't always straightforward—it depends on what you're printing, your quality expectations, and how you define “fast.” Here's how the two technologies stack up:

Print Time per Model

FDM: Builds objects by extruding filament line by line. Print speed varies with the complexity and infill of the model. A single medium-sized object (e.g., 10 cm tall) can take 3–8 hours.

Resin: Prints layer by layer, curing entire slices at once. Speed is primarily determined by the model's height, not volume or complexity. A similar object might take 2–5 hours on a fast resin printer.

Winner: Resin printers tend to be faster for smaller and medium-height objects with high detail, especially when printing multiple parts at once.

Print Speed for Batch Printing

FDM: Printing multiple objects takes proportionally longer, as the nozzle must travel to each part individually.

Resin: Can print several objects at once without increasing print time, as long as they fit within the build area and share the same height.

Winner: Resin, especially for high-volume, small-part production.

Setup and Post-Processing Time

FDM:

Faster setup: Load filament, level bed, and start.

Post-processing: Mostly limited to support removal and surface smoothing if needed.

Resin:

Longer setup: Pour resin, level plate, check settings.

Post-processing: Requires washing in IPA and UV curing, which can add 20–40 minutes or more.

Winner: FDM is faster overall in total workflow when including post-processing.

Speed with Detail Tradeoff

FDM: Speed can be increased at the cost of layer visibility and reduced print quality.

Resin: Maintains high resolution even at higher speeds, especially with modern MSLA printers.

Winner: Resin maintains better detail even when printing quickly.

Which Should You Choose for Speed?

When speed is your top priority, choosing between FDM and resin depends on the specific requirements of your project:

Choose Resin Printing if:

You're producing high-detail models like miniatures, dental parts, or jewelry.

You need to print multiple small objects quickly and simultaneously.

Post-processing time is acceptable given the time saved during printing.

Choose FDM Printing if:

You're printing larger objects or prototypes where fine detail is less important.

You want a faster overall workflow, including setup and cleanup.

You prioritize ease of use and minimal post-processing.

Ultimately, while resin printers often provide faster per-model printing speeds and superior detail, FDM printers can be more efficient for large, low-detail objects and have shorter turnaround from start to finish. For many users, the best solution may be to use both technologies—choosing the one that best fits the job at hand.

/webresources/Blog/1745909931196.jpg)

/webresources/Blog/1745894126997.jpg)

/webresources/Blog/1745816394311.jpg)